Refurbishment Equipment: The Machinery Behind Quality at Phonebot

The smartphone market is a whirlwind of innovation, with each year bringing cutting-edge advancements from giants like Apple and Samsung. While this rapid evolution is exciting, keeping up with the latest models can be daunting, let alone expensive. This is where refurbished mobile phones offer a compelling alternative. As the demand for high-quality pre-owned devices surges, refurbished phones have emerged as a smart choice, offering significant savings without compromising on performance. No longer do you have to ponder, "Should I fix my phone or get a new one?" Reconditioned mobile phones provide a reliable solution that blends quality with affordability. Whether you're upgrading your current phone or purchasing your first smartphone, opting for a refurbished device is a sustainable and eco-friendly choice.

At Phonebot, we are pioneers in the refurbishment market, dedicated to transforming second-hand phones into high-quality, like-new products. Our rigorous refurbishment process includes comprehensive inspections and advanced repair techniques. In this article, we will dive into the detailed steps we take to restore each device, from initial inspection to final quality control, highlighting the advanced tools and methods we use to restore each device to its optimal condition.

What Does "Refurbished" Mean at Phonebot?

At Phonebot, refurbishment goes beyond simple repairs. Each device undergoes a comprehensive 72-point inspection, covering critical aspects such as hardware integrity, software functionality, battery health, and cosmetic condition. We focus on key areas like screen repairs, battery replacements, and overall performance optimization to ensure every device meets our high standards. This rigorous process ensures that all refurbished phones, including popular models like the refurbished iPhone, Samsung, and Google Pixel devices, deliver like-new quality and reliability.

Our 72-point inspection and grading system ensures accuracy - here's what customers experience:

"Purchased 2 iPhone XS mobile phones. Both phones were in as new condition as stated and both phones 100% battery when stated battery would be 85% and over. Very happy with the phones and aftersales service. I rate them as a 10/10 for quality and service."

Phonebot Customer Review - Reviews.io

Detailed Refurbishment Process

72-Point Inspection

The first step in our refurbishment process is the comprehensive 72-point inspection. This thorough evaluation is designed to assess and verify the overall condition and functionality of each device before it undergoes further refurbishment. This comprehensive process is divided into three critical phases:

Physical Condition

We begin by thoroughly evaluating the device’s exterior for any signs of damage. This involves checking the phone screen for cracks, scratches, or other visible defects. The device’s casing and buttons are inspected to ensure they are intact and functioning properly. Any cosmetic imperfections are noted for correction during reassembly and polishing. This step is crucial for identifying issues that could affect the device's appearance and user experience.

Internal Components

After assessing the physical condition, we turn our attention to the internal components. This includes checking the battery health, charging ports, and connectors for any signs of wear or damage. We employ advanced diagnostic tools such as the JCID BLE X-12PM Baseband Logic Chip EEPROM Data Reading and Writing Programmer. This tool is essential for reading and writing data from baseband logic chips, ensuring their proper functioning. It helps us identify any potential faults within the internal circuits that could impact the device’s performance.

Software Performance

The final stage of the inspection focuses on software performance. We run a series of diagnostic tests to check for software updates and ensure that security patches are up-to-date. Comprehensive testing is conducted to verify that all applications function correctly and that connectivity features such as Wi-Fi, Bluetooth, and cellular data are operating as expected. This step is vital for confirming that the device is not only physically sound but also fully operational from a software perspective.

Component Repair and Replacement

Once the initial 72-point inspection is complete, we move on to the component repair and replacement phase. This step is essential for addressing any defects identified during the inspection and ensuring that each device operates at its best. One of the essential tools in our refurbishment process is the 2UUL Mini Electric Grinder Engraving Pen.

This tool is instrumental for detailed repair work on integrated circuits (ICs) and CPUs. Its precision allows our technicians to perform intricate repairs and adjustments, which are essential for fixing delicate components without causing additional damage. Whether it’s repairing minor chips or enhancing connections, this tool ensures high-quality, reliable repairs.

For repairing and replacing other internal components, we utilize the Relife RL-936W Spot Welder. This machine is designed for securing connections on circuit boards, which is crucial for fixing issues related to solder joints and component attachments. Its precision ensures that repairs are reliable and durable, maintaining the integrity of the device’s internal systems.

For devices that require a phone screen repair, the LCD Screen Separator Machine is an invaluable tool.

This tool is used to remove old screens and install new ones safely. The machine uses heat to soften the adhesive holding the screen in place, allowing for a clean separation without damaging the device. This ensures that the new screen is perfectly aligned and free from bubbles or imperfections.

Data Recovery and Software Reinstallation

The data recovery and software reinstallation phase is critical in the refurbishment process at Phonebot. This stage ensures that every device not only functions correctly but also has up-to-date software and firmware, enhancing performance and security.

Data Recovery

The first step in this phase is to address any data recovery needs. We use advanced tools to extract and recover any valuable data that may be present on the device. This is particularly important if the device was previously in use and had data that needs to be preserved or transferred. Our technicians handle this process with the utmost care to ensure that no data is lost or corrupted during recovery.

Firmware Updates and Software Reinstallation

Once data recovery is complete, we proceed with firmware updates and software reinstallation. Keeping the device's firmware up-to-date is essential for ensuring compatibility with the latest applications and security protocols. For this, we utilize the JCID P13 NAND Read/Write Programmer. This advanced tool enables precise reading and writing to NAND flash memory, ensuring that the firmware is updated accurately.

Following the firmware update, we reinstall the device's operating system and essential software. This step involves setting up the latest version of the OS to enhance performance and ensure all system functionalities operate smoothly.

Reassembly and Polishing

After the rigorous component repair and software reinstallation processes, the next crucial step is reassembly and polishing. This phase ensures that the device not only functions flawlessly but also looks as pristine as when it was first manufactured.

Reassembly

Reassembling a device requires precision and care to ensure all components fit together seamlessly. Our technicians use the Kuiper UN9, a highly effective tool for reassembling mobile phones. This device aids in the precise alignment of internal components and ensures that every part is securely and correctly placed. The Kuiper UN9 helps to avoid common issues such as misalignment or improper connections that can affect the device's performance.

Additionally, we use an adjustable Trinocular Zoom Stereo Microscope for Mobile Phone Repairing to closely inspect the device during reassembly. This microscope allows our technicians to examine tiny details and connections that are not visible to the naked eye. By magnifying the device’s internal components, the microscope ensures that all parts are perfectly aligned and securely attached, which is essential for the device’s overall functionality and longevity.

Polishing for a Like-New Finish

Once reassembled, the device undergoes a thorough polishing process to restore its cosmetic appearance. This step involves carefully cleaning and buffing the exterior to remove any smudges, scratches, or blemishes. Our polishing process ensures that the device looks as good as new, enhancing its aesthetic appeal and preparing it for sale.

Using advanced cleaning tools and techniques, we address any cosmetic imperfections, ensuring the device has a smooth, glossy finish. The final result is a refurbished device that not only performs at its best but also has a visually appealing look, providing customers with a high-quality product that meets Phonebot’s stringent standards.

Final Quality Control

Before a refurbished device is ready for sale, it undergoes a meticulous final quality control check. Performance testing is the first step in this phase. Each device is thoroughly assessed to ensure all features function correctly, including the touchscreen, camera, battery life, Wi-Fi, and Bluetooth. Specialized diagnostic tools identify any hardware or software issues to confirm the device performs reliably under various conditions.

Aesthetic inspection follows, checking for scratches, dents, or discoloration. The screen, buttons, and casing must meet like-new standards, with minor flaws polished or replaced. This level of detail is essential for devices like refurbished Samsung phones, known for their premium design and high-performance features. Only after passing these checks is the device approved for sale, ensuring top-tier quality for our customers.

Our final quality control process ensures every device meets like-new standards - here's proof from a recent customer:

"I recently purchased an iPhone 15 from this company. They had rated it Grade A. I was amazed by its pristine condition - not one mark on the screen or anywhere else. The battery health showed 100% and the phone had only been through 33 battery cycles. I am super impressed and highly recommend buying from them."

Phonebot Recent Customer, Trustpilot.

Advanced Machinery and Tools

The refurbishment process at Phonebot is a blend of meticulous craftsmanship and cutting-edge technology. Our commitment to quality is evident through the sophisticated machinery and tools employed to restore devices to their optimal condition. Here’s an insight into some of the other high-tech tools that play a crucial role in our refurbishment process:

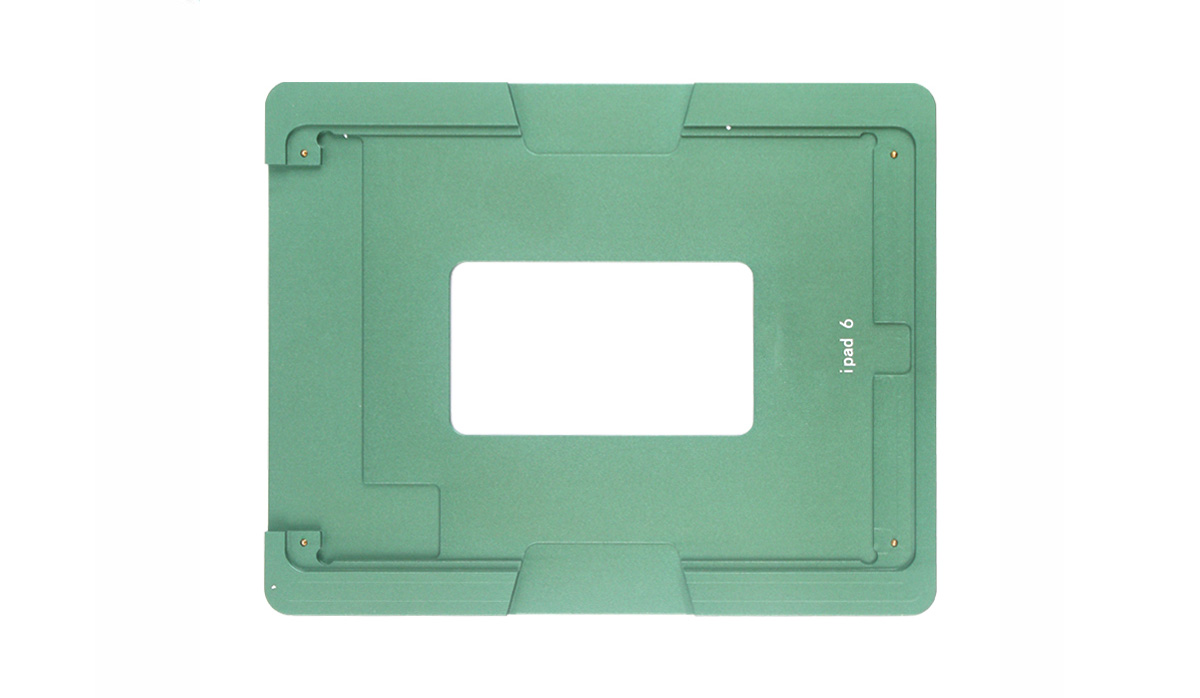

iPad Series LCD Alignment Mold

The iPad Series LCD Alignment Mold is indispensable for ensuring accurate alignment of front glass on LCD screens. This mold plays a vital role before laminating the screen, guaranteeing that components fit perfectly. Proper alignment minimizes defects and enhances the visual appeal of refurbished screens. Using this mold ensures that the final product meets high standards, essential for achieving high-quality cracked screen repair and reconditioned mobile devices.

WYLIE 4-in-1 Multi-Purpose Phone Repair Fixture Kit

The WYLIE 4-in-1 Multi-Purpose Phone Repair Fixture Kit is an essential tool designed to streamline various aspects of mobile phone repair. Its multifunctional capabilities make it a valuable asset for technicians dealing with diverse repair needs. Its 360° rotatable design allows technicians to access different angles easily during repairs, improving efficiency and reducing the risk of damage.

DC Power Supply Variable 30V 10A

A stable power source is essential for effective repairs. The DC Power Supply Variable 30V 10A provides precise voltage and current adjustments. With its 4-digit LED display, this tool ensures accurate power delivery, facilitating effective testing and powering of devices before final assembly. Its reliability is critical for maintaining the functionality of refurbished devices and ensuring thorough refurbishment checks.

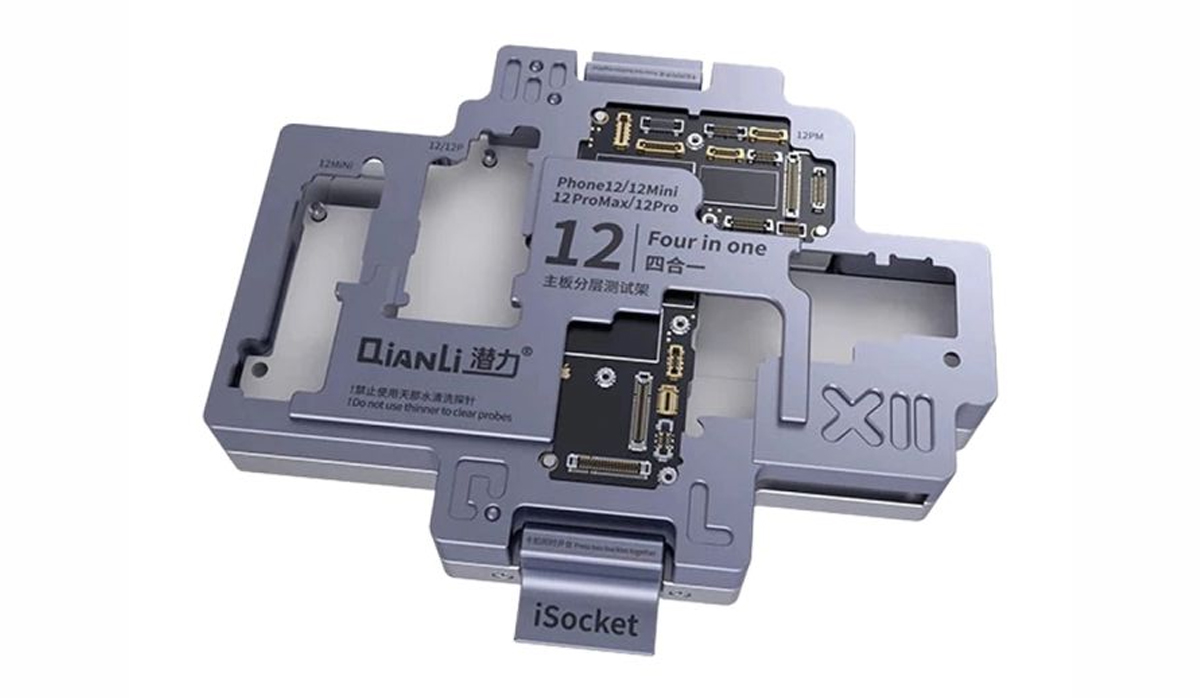

New Qianli Dot Matrix Repair Fixture

The New Qianli Dot Matrix Repair Fixture is specialized for Face ID repairs on iPhones. This fixture offers a stable platform for testing and repairing the Face ID lattice, allowing technicians to perform delicate operations with precision. The fixture's design simplifies the repair process, ensuring that the Face ID function is restored accurately. It provides a reliable and secure work surface, thus enhancing the quality of Face ID repairs.

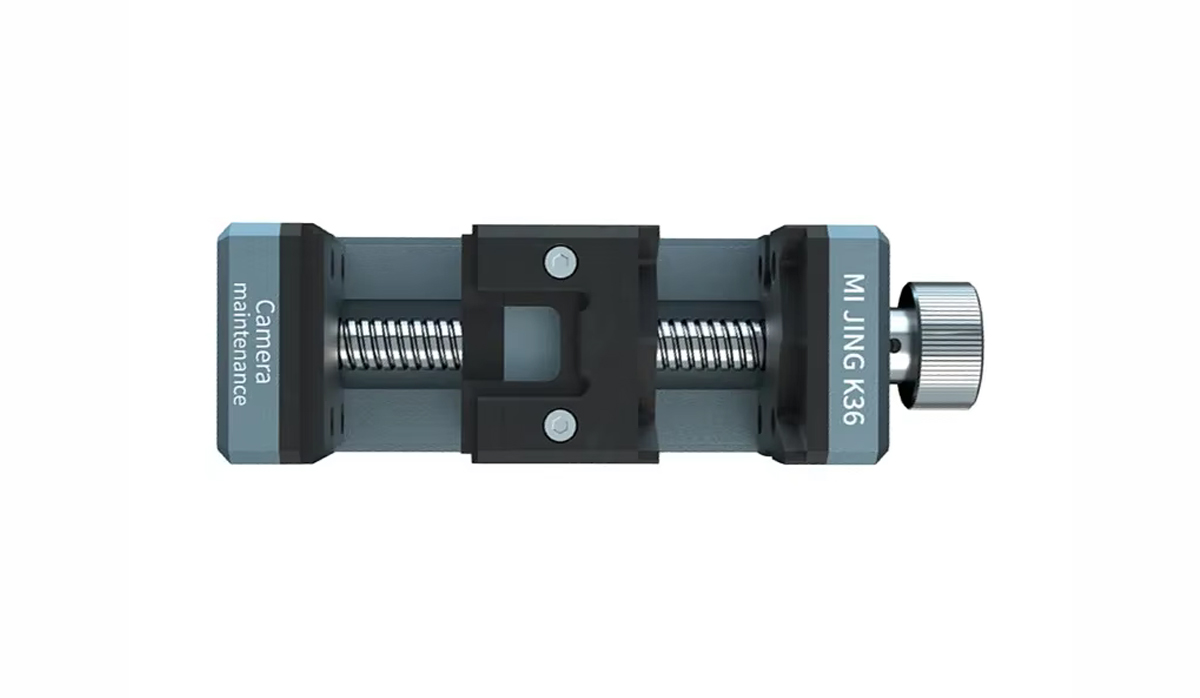

MI Jing K36 Mobile Phone Camera Repair Fixture

The MI Jing K36 Mobile Phone Camera Repair Fixture is specifically designed for repairing mobile phone cameras. It facilitates precise desoldering and welding of camera components, ensuring that reconditioned mobile devices have fully functional and high-quality cameras.

This fixture is crucial for maintaining the integrity of camera systems during repairs, resulting in high-quality refurbished phones with excellent camera performance.

Short Killer Mobile Phone PCB Short Circuit Repair Tool Box

The Short Killer Mobile Phone PCB Short Circuit Repair Tool Box is essential for diagnosing and repairing short circuits on circuit boards. This tool enables efficient troubleshooting and repair, crucial for maintaining the functionality of refurbished devices. Its effectiveness in diagnosing issues helps ensure that repairs are completed swiftly and accurately.

Mechanic IT3 Pro Intelligent Heating Pad

The Mechanic IT3 Pro Intelligent Heating Pad is designed for delicate motherboard repairs, integrating functions such as tin planting, desoldering, and glue removal. Its controllable temperature settings and plug-and-play design streamline the repair process for layered IC chips. This heating pad is ideal for handling intricate tasks and improving the quality of refurbished devices, reducing maintenance time, and ensuring reliable repairs.

Qianli iPinch IC Chip Motherboard Fixture

The Qianli iPinch IC Chip Motherboard Fixture securely holds various motherboards during repairs. Made from durable aluminum alloy, this fixture provides stability and ease of use, making it perfect for intricate repairs.

Its innovative design allows for quick installation and removal, making it portable and convenient. The fixture enhances the efficiency of intricate repairs by providing a stable work surface, ultimately improving the quality of the refurbishment process.

T36 Nano Soldering Station

The T36 Nano Soldering Station features a rapid heating system and magnetic induction sleep feature, allowing for quick temperature adjustments and enhanced safety. Its precision control is ideal for delicate soldering tasks, minimizing the risk of damage to sensitive components. The soldering station's efficiency and accuracy contribute to high-quality repairs, ensuring that refurbished devices meet stringent performance standards.

Inside Phonebot Refurb Lab: Tools & Techniques

Unlike many “refurbishers” who simply wipe phones and resell them, we operate an in-house repair and refurbishment facility equipped with:

- Doctor Phones software for grading & reporting

- JCID EEPROM Programmers (BLE X-12PM)

- Relife RL-936W Spot Welders

- LCD Screen Separators and Alignment Jigs

- ESD-compliant workstations for safe internal repairs

Our team is trained to follow SOPs based on ISO 9001:2015, ensuring quality, repeatability, and traceability in every step of the process.

We test and refurbish over 1,000+ devices every month and back them with warranties and compliance under Australian Consumer Law.

The consistency of our refurbishment process keeps customers coming back - here's what repeat buyers say:

My family has purchased numerous devices (6 phones, 2 iPads) from Phonebot over the years. The condition of the used/refurbished items has always been a pleasant surprise.

Phonebot Customer review - productreview.com.au

Why Choose Phonebot Refurbished Devices?

With so many options available in the refurbished market, you may wonder why Phonebot stands out among the competition. Here are a few compelling reasons to choose our refurbished devices

Cost Savings

Refurbished mobile phones from Phonebot are typically available at significantly lower prices than their brand-new counterparts. This cost-effectiveness allows you to access high-quality smartphones without breaking the bank.

Environmental Impact

Choosing refurbished helps reduce electronic waste and conserves resources. Our refurbishment process minimizes environmental impact by extending the lifecycle of devices and reducing the need for new materials, making it an eco-friendly choice.

Warranty and Support

We offer a robust warranty policy, including a 30-day battery replacement guarantee for older models and a 12-month warranty for "Grade A" and "Like New" devices.

Trustworthy Refurbishment

Phonebot's commitment to quality and reliability means you can purchase with confidence. All refurbished phones are meticulously checked, reassembled, and polished to ensure they perform like new, backed by our 1-3 day processing time for refunds and replacements.

Free Delivery

At Phonebot, we believe that convenience should go hand in hand with quality. That's why we provide free delivery on all orders, ensuring you receive your refurbished device without any extra shipping costs. Our efficient delivery process guarantees that your new gadget arrives promptly and securely at your doorstep.

Returns and Refunds

When you opt for refurbished devices at Phonebot, you enjoy not only significant savings but also peace of mind with our customer-centric returns policy. If you change your mind, you can return the product within 7 days of receipt, with certain exclusions. We prioritize getting you the right product and will process refunds or replacements within 1-3 working days, subject to product availability.

Wrap Up

At Phonebot, refurbishment isn’t a buzzword, it’s a meticulously engineered process backed by advanced tools, certified workflows, and years of technical expertise. From our 72-point inspection to precision repairs with industry-grade machines like JCID programmers and LCD separators, every step is designed to restore devices to like-new performance and appearance.

We don’t just fix phones, we recondition them to meet exacting quality, reliability, and aesthetic standards. With in-house technicians trained on SOPs aligned with ISO 9001:2015 and tools certified for diagnostics and data handling, our facility stands among Australia’s most advanced refurb labs.

Whether it’s a refurbished iPhone, Samsung, or Google Pixel, you're not just buying a used phone, you're getting a thoroughly tested, expertly repaired device backed by warranty, free delivery, and compliance with Australian Consumer Law.

In short, we don’t cut corners. We rebuild tech for real life.

Posted by Liam Harris

Liam Harris

I’m Liam Harris, a tech writer at Phonebot with a passion for technology. I provide trusted insights on refurbished phones, tablets, and accessories, focusing on quality, sustainability, and affordability. With a solid understanding of the refurbished market, I offer practical tips, product comparisons, and the latest tech updates to help you make informed decisions. My goal is to connect you with high-quality devices that fit your budget and lifestyle. Stay tuned for more on the best in refurbished tech here at Phonebot.

Hot Deals

Hot Deals

Google

Google Apple

Apple Facebook

Facebook